5 Common Classes of Girth Gear Potential Failure Modes

Tooth Fracture is generally considered an ultimate failure of the gear set as is often results in the inability to rotate the set.

Here are 5 classes of girth gear potential failure modes that can be detected and mitigated with routine inspections:

Wear-Abrasion

Abrasive wear is the removal or displacement of material along the tooth flank due to the presence of hard particles. These particles can come from external sources such as slurry, dust, contamination, or may be self-generated hard metal fragments from other failure modes such as macropitting or scuffing.

The tooth profile is most affected resulting in poor mesh action and localized overloading.

Note: Often severe wear will progress to macropitting as contact stresses increase from localized overloading

Scuffing

Scuffing is a severe form of adhesive wear caused by the transfer of material from one tooth surface to another due to microwelding and tearing.

Scuffing occurs when the lubricant film cannot completely separate the metal surfaces. Machining marks are removed and deeper craters are observed. In the severe form surface temperatures may become significantly elevated causing localized metallurgical changes to occur. Proper lubricant usage and application is the best prevention.

Note: Severe scuffing can initiate flank cracks

Plastic Deformation (Indentation)

Indention is caused by hard foreign material that becomes trapped between mating teeth, causing an indentation in the tooth surface. The area around the indentations is typically raised from plastic deformation of the metal.

Note: Severe scuffing can initiate flank cracks

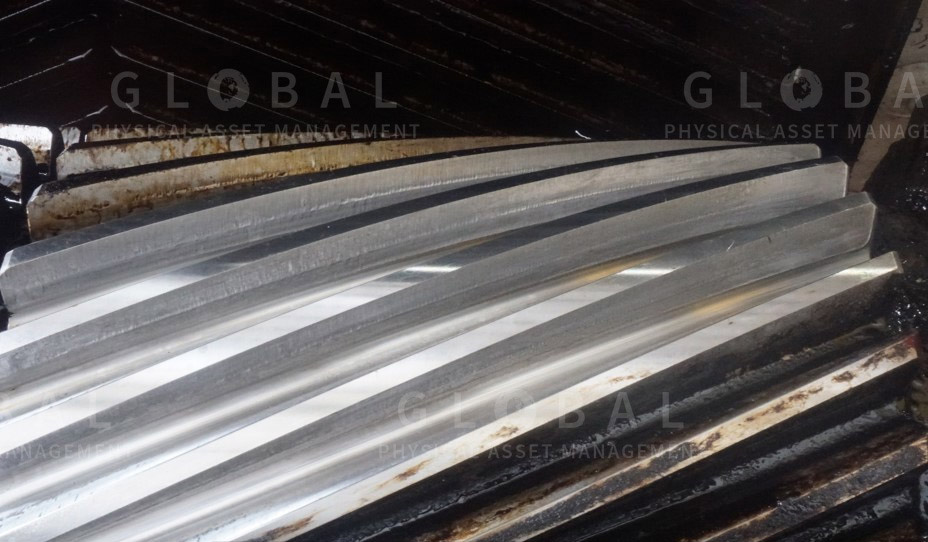

Plastic Deformation (Cold Flow, Tip to Root Interference, Tight Mesh)

The topland of this gear is completely rounded from plastic deformation where the gear is in tight mesh with the pinion and experiencing tip to root interference.

Note: Significant edge burrs have developed form the tight mesh condition

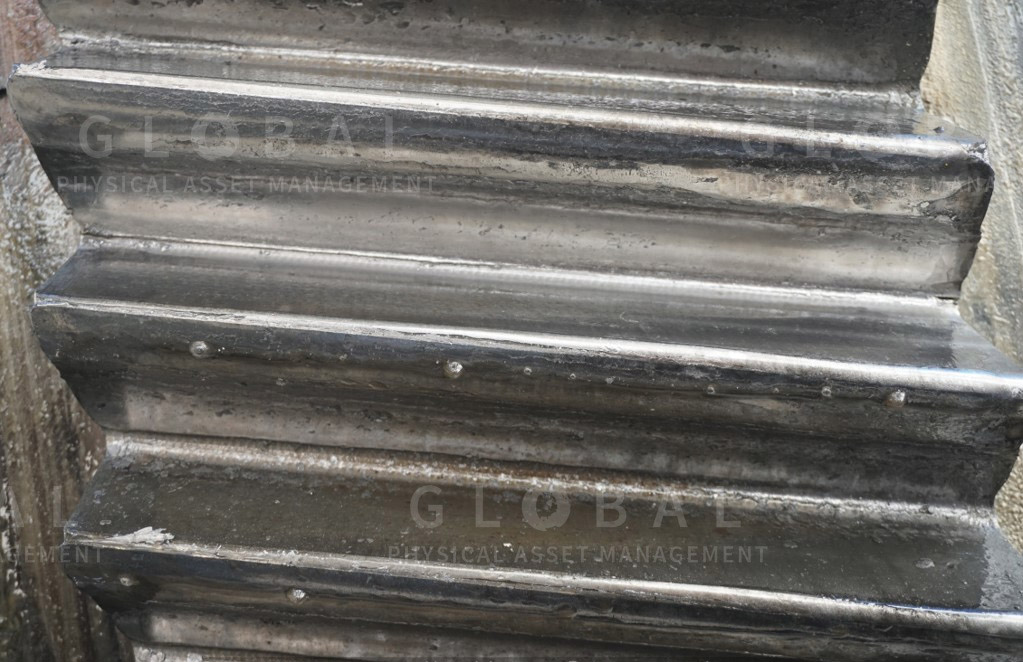

Hertzian Fatigue (Spalling)

Spalling occurs when macropits form, then grow is size and coalesce into larger cavities on the gear tooth surface. Asperities and high pressures from variations in manufacturing tolerances. This form of macropitting quickly stops once the load redistributes. The image adjacent is a gearbox gear, showing spalling across the entire face.

Note: Spalling can be easily identified from stop action photographs of pinion teeth. This is a severe failure mode which can quickly lead to tooth cracking and fracture.