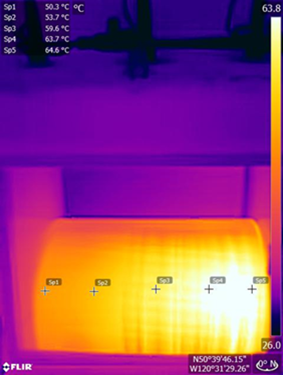

Online pinion temperature monitoring of the pinion with infrared temperature sensors is the most consistent and effective means of detecting misalignment of gear driven mill systems, allowing the user to quickly detect and correct any misalignment that may develop.

A common failure cause of gear driven mill systems is misalignment, which in its most severe form can cause rapid tooth fatigue and fracture. The operating temperature profile of girth gear pinions give an indication of the pinion’s overall alignment with the girth gear. High differential temperatures from end to end indicate misalignment.

This system was designed to allow continuous sensing of the pinion temperatures with infrared sensors and can be integrated into most DCS systems. The housing design prevents lubricant and other contaminants from interfering with the sensors, providing reliable operation.

Benefits:

- Continuous condition monitoring through automatic sensing of pinion bulk temperatures.

- Designed to operate in the harsh environment of the gear guard.

- Highly reliable components.

- Easily fitted to most gear guards.

Other Customized Solutions:

- Trunnion bearing temperature monitoring

We pride ourselves on being able to provide realistic and site specific (RCM) based maintenance plans and solutions to improve critical asset reliability and up-time.