Complete Inspection Solutions for Crack Assessment of Carbon Steel Pipelines

Pipelines are the most efficient way of transporting large quantities of liquids and gas. Their safety is critical and assessing fatigue cracks and stress-corrosion cracking is essential.

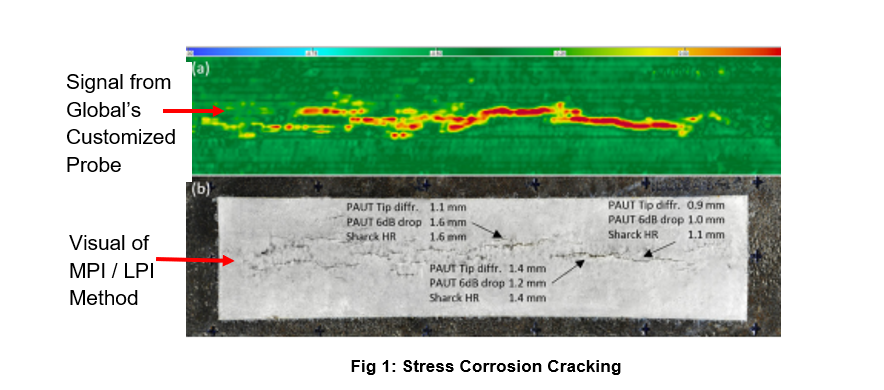

Magnetic-Particle Inspection (MPI) and Liquid-Penetrant Inspection (LPI) are often used effectively to detect cracks. They are, however, impractical with known drawbacks—surface preparation, manual length sizing, lack of digital data. Global’ s pipe probes are designed around eddy current array; a better way to scan for fatigue cracks and stress-corrosion cracking (SCC). Use with Global’ s portable test instrument; this is one of the most powerful integrated solution for pipeline integrity on the market.

Using Global’s technology to assess cracks in pipelines, instead of MPI or LPI, the owner benefits from:

- Fastest solution on the market; 60-70% faster than MPI / LPI

- Surface-breaking cracks detection and sizing in one scan

- Interlinking cracks detection

- Very repeatable results

- Less user dependence

- In-service inspections

- Solution unaffected by weather conditions

- Minimal surface preparation necessary

- User-friendly interface with data analysis assistant