Maximizing equipment availability, and minimizing greenhouse gas emissions with predictive maintenance

More and more countries, regions, cities and companies are establishing carbon neutrality targets

This trend is very noticeable in the mining sector and has created many new business opportunities for early movers.

“The relationship between equipment reliability and CO2 emissions is quantified

… has the potential to increase the efficiency and productivity of the mining equipment and can be used to contribute to equipment management towards more sustainable mining operations.”

Source: Equipment Management Towards Sustainable Mining, 2020

Equipment reliability and availability are critical to productivity

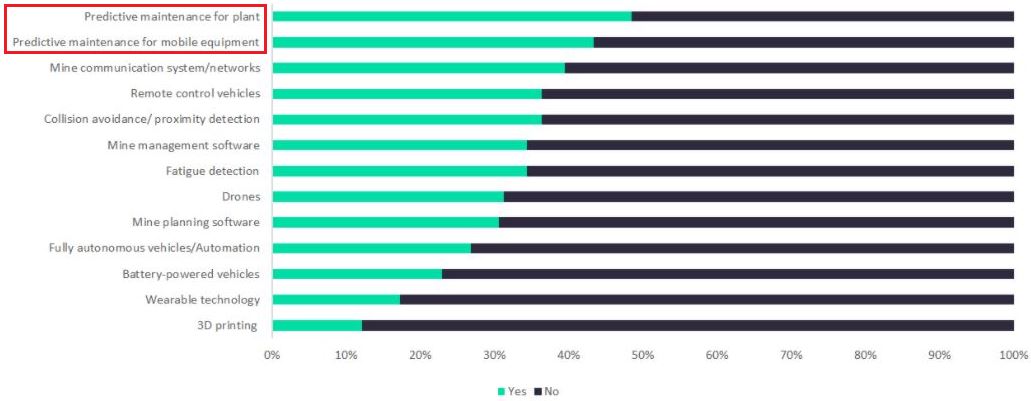

GlobalData’s mine-site survey asked miners, “In which of the following do you expect to invest in / invest further in, over the next 2 years?”

Source: mining-technology.com

Operational Benefits & Outcomes of Sustainable Operations

| Innovation | Features | Benefits | Outcomes |

|---|---|---|---|

| OTR OnSite™ | Onsite predictive maintenance | Reduced inventory | Higher productivity, Less downtime, Higher reliability |

| No need to send OTR Assemblies offsite | Reduced logistics & lead times | ||

| OTR Assemblies that fail can be scraped at site | Less CO2 from reduced shipping | ||

| Inspect critical areas in 5 minutes | Maintenance cost improvement | ||

| Crusher Vision™ | Automated System | Improved mantle and concave wear cycles | |

| Laser emitter | Increased safety | ||

| Camera for laser imaging | Increase throughput | ||

| Graphical user interface | Power consumption improvement | ||

| Reduce operating costs (TCO) | |||

| Maintain the forecasted numbers | |||

| IsaMill™ and Jameson Cell Support | Mechanical Mill Inspections and commissioning | Continuous improvement | |

| Full installation support | Increased wear life | ||

| Maintenance and Operational training | Maintenance cost improvement | ||

| Continuous improvement solutions | |||

| Service, engineering and aftermarket |

Global-PAM’s Economic and Social Impacts

Economic

- Our products produce high data accuracy

- Increasing production revenue

- Ease of use for the operator

- Power usage efficiency

- Easier maintenance protocols

- Time and cost savings before, during, and after production

Social

- Enhanced safety for the user of the equipment

- Reduced downtime

- Lower exposure to hazards

- Safer work environment

- Enhanced safety practices taught

Sustainable Development Goals (SDGs)

At the heart of “Agenda 2030” are the 17 Sustainable Development Goals (SDGs) that address the most important economic, social, environmental and governance challenges of our time. The SDGs have been negotiated at the United Nations with widespread public input, including significant involvement by companies participating in the United Nations Global Compact, the world’s largest corporate sustainability initiative.

Global-PAM Reducing Environmental Contamination

In our chemical division, our spent product, in some jurisdictions, can be disposed of after as a waste oil (used as bunker fuel). We are currently developing a low VOC formulation to do our part in reducing environmental contamination.

Global wants to make the planet a healthy and better place to be. We are open to suggestions that you might have on sustainability incentives and programs.

Global-PAM Empowering Communities

At Global, we know of the impact that our community and other communities have on us. We try to give back as much as we can throughout the year. At Christmas time, we like to donate to the local food-banks or women’s shelters.

Additionally, whenever we visit other communities we always make sure to treat everyone and everything with the utmost respect. We are guests at these places and act as such. We want to improve these mines and their equipment, so they can improve the surrounding communities economy and social life.