- Toll Free USA +1 (866) 419-1619

- Worldwide +1 (715) 214-2162

- info@global-pam.com

Search

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

Skip to content

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

Downloads

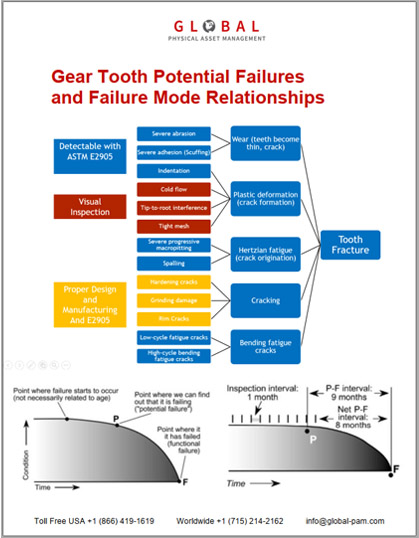

Gear Tooth Potential Failures and Failure Mode Relationships

The fracture of gear teeth has evident operational consequences. This failure mode results in extended downtime while the gear and pinion are replaced. If a spare is not available the downtime can be catastrophic.

Category: Print