- Toll Free USA +1 (866) 419-1619

- Worldwide +1 (715) 214-2162

- info@global-pam.com

Search

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

Skip to content

- Company

- Girth Gear Solutions

- Mill, Kiln & Girth Gear Risk Assessments

- Girth Gear Reliability and Failure Analysis

- Physical Asset Management

- Failure Analysis and Contingency Planning

- The Importance of Girth Gear Cleaning and Flushing

- Operational and Maintenance Support Fixed Plant

- Automated Continuous Pinion Temperature Monitoring System

- Mill Shell Mapping

- Kiln Inspections

- Mobile Equipment

- Crushing

- Other

- Downloads

Downloads

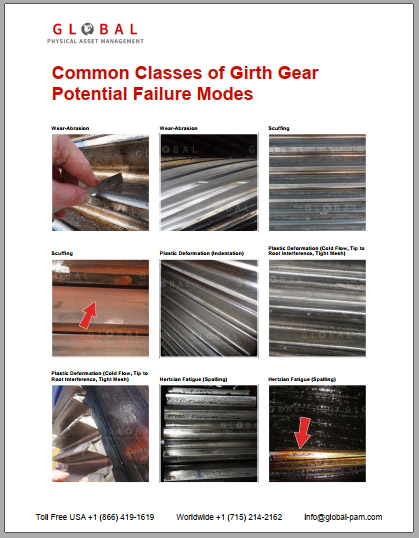

Common Classes of Girth Gear Potential Failure Modes

Abrasive wear is the removal or displacement of material along the tooth flank due to the presence of hard particles. These particles can come from external sources such as slurry, dust, contamination, or may be self-generated hard metal fragments from other failure modes such as macropitting or scuffing.

Category: Print