Crusher Vision™ Patented Automated Closed Side Setting (CSS) System

Crusher Vision is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle.

Crusher Vision has developed patented novel technology that offers the mining sector the opportunity to increase throughput, decrease maintenance costs, decrease power consumption and greatly reduces the safety concerns by implementing a system for non-disruptively measuring wear on gyratory crushers.

Crusher Vision was developed to minimize down-time when assessing wear on gyratory crusher mantles and concaves in the mining sector.

Current methods of assessing wear are inaccurate, dangerous and require that the equipment be shut down for at least an hour, which results in production losses. In contrast, Crusher Vision can measure the CSS when the crusher is operating, but empty, allowing an operator to obtain results within a few minutes. As there is little or no downtime, readings can be taken daily with little impact on productivity. With accurate data, a mine can trend the mantle liner daily, predict mantle liner life and plan mantle liner changeouts with accuracy.

Crusher Vision will:

- Improve the planning of mantle and concave wear cycles

- Reduce energy consumption

- Reduce downtime for crusher operation

- Improve throughput

- Reduce operating costs (TCO)

- Reduces safety concerns

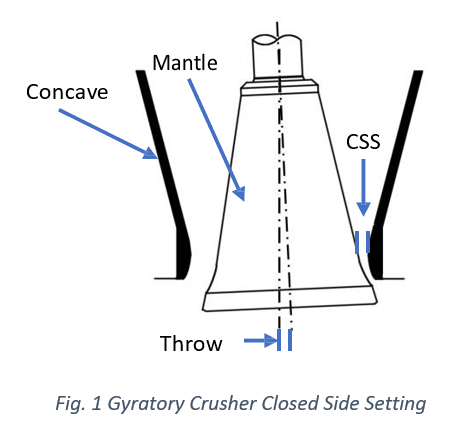

Crusher Vision is an automated system for determining closed-side setting (CSS) in a gyratory crusher by measuring the gap between the concave and mantle, as shown in Fig. 1.

The standard method for determining wear on the mantle is to lower a galvanized steel bucket or a lead ball into the crusher then measuring the amount of deformation on the bucket or lead ball.

This method is highly inaccurate, time consuming and poses significant physical risk to the operator.

When the system, utilized daily, the crusher tonnage or production is maintained at the forecasted numbers. Too tight of setting reduces tonnage and can adversely affect the crusher mechanics and motor amp draw. If the CSS is too large it will affect choke feed as it cannot be maintained and will send coarse material to the mill reducing tonnage and crusher effectiveness.

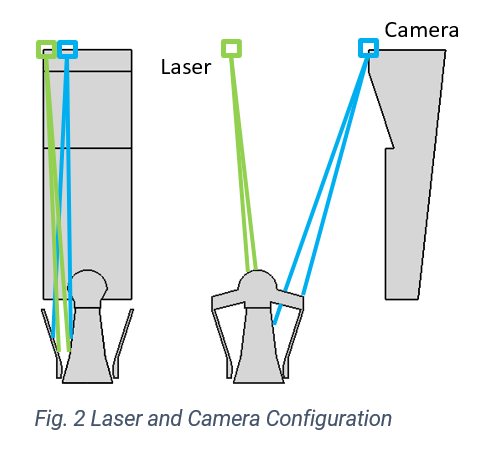

Crusher Vision includes a laser emitter, a camera for collecting laser images and a computer for calibrating the system and collecting and processing data. An illustration of laser and camera configuration is shown in Fig. 2.

In operation, the system is calibrated when the mantle is changed. The CSS can then be determined at any time that the crusher pocket is clear of material by activating the laser emitter and collecting images of the laser trace. The camera captures images at 4 frame per second, giving 20 frames per revolution of the mantle.

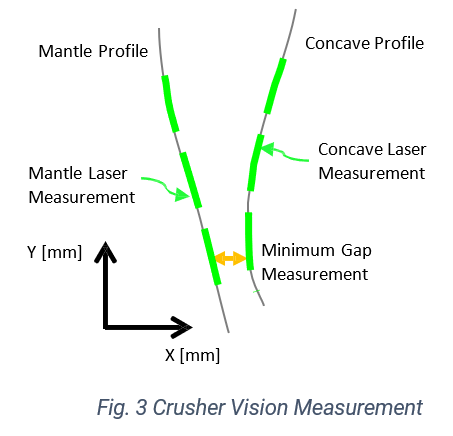

The system is programmed to capture frames within approximately 15-20 seconds. An illustration of the Crusher Vision system measurement result is shown in Fig. 3.

Impact on the Mining Sector

Open pit mining worldwide utilizes gyratory crushers as the primary crushing circuit that feeds the mills. In some cases, the mantles are changed approximately every seven weeks at a cost of approximately $150,000 each time.

It is expected that the present technology will result in at least one less changeout per year. At one large open pit mine, for one crusher, the reduction of downtime translates into increased productivity of about 780,000 tons annually, based on production of 20,280,000 tons annually.

The replacement of crusher operators with the system saves a mine about $500,000 a year in North America.