We provide failure Analysis and contingency planning for mill and kiln drivetrains; from operation & maintenance support to end of life.

Logistic Support

- Resource support plans, total cost of ownership.

- Training programs

- Optimization of insurance spend, maintenance spend, and sparing costs.

Operation and Maintenance Support

- RCM (Reliability Centered Maintenance Program) approach to maintenance, and audits of existing maintenance plans

- Preventative maintenance tasks, tied to specific failure modes.

- Predictive maintenance tasks, to detect potential failures.

- Girth Gear Inspections per ASTM E-2905

- Structural Inspections, Shells, Heads, Trunnions, Rollers, Riding Rings

- Operational inspection tasks and intervals

- One time or engineering changes can be implemented where the probability of failure and consequences of failure are deemed unacceptable.

End of Life Support

- Provide a procedure for inspection and verification on suitability for open

gear and pinion flipping. - Provide a framework and decision making process for replacement gears.

- Assess alternative solutions to scrapping old gearing, dependent on condition and structure.

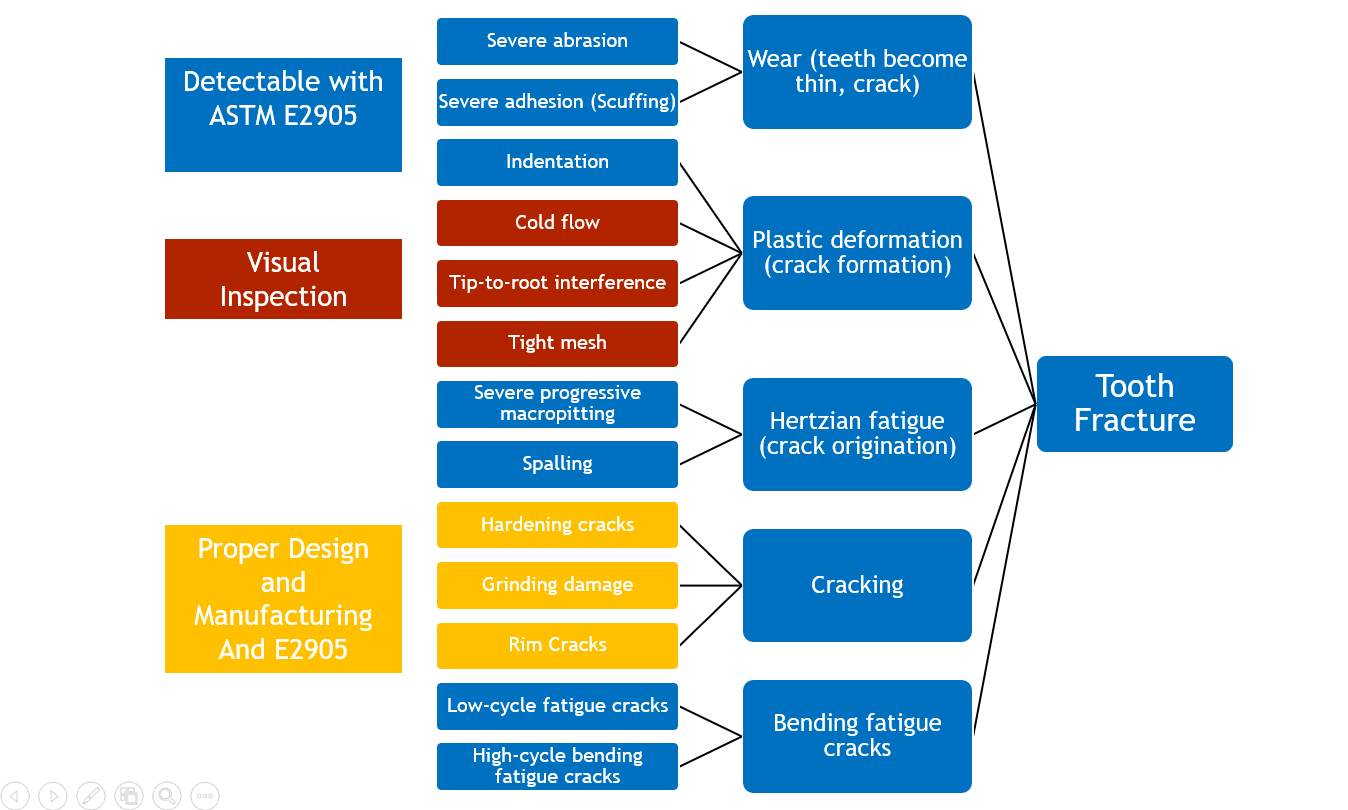

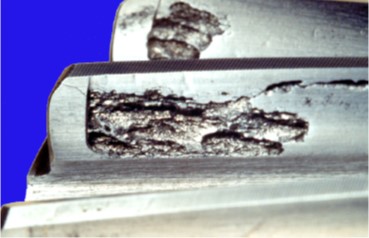

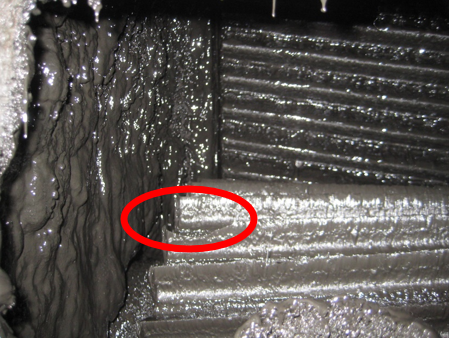

Girth Gear Failures

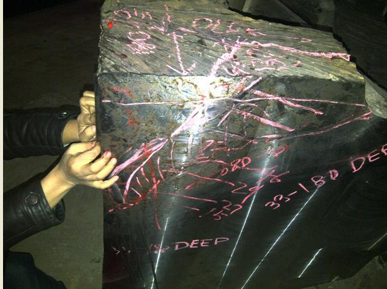

Inspections of the gear teeth are necessary to detect crack formation, spalling, severe wear and other potential failures

Girth Gear System Function

To rotate a cylindrical drum by transferring and increasing torque from a high speed shaft to a low speed girth gear.

Girth Gear Functional Failure

Gear cannot transfer torque.

Pinion cannot transfer torque.

Failure Modes:

- Structure failure

- Joint failure

- Tooth fracture (predominant mode)

Failure Effects from Tooth Fracture:

- When a tooth fractures the effects can include high vibrations, loud noises as the broken section comes through mesh, additional teeth break from impact of the broken section. The gear and pinion will likely need to be replaced.

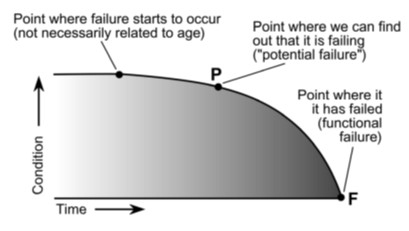

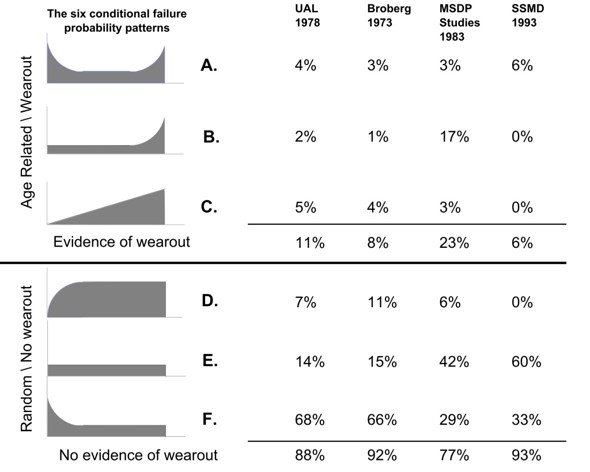

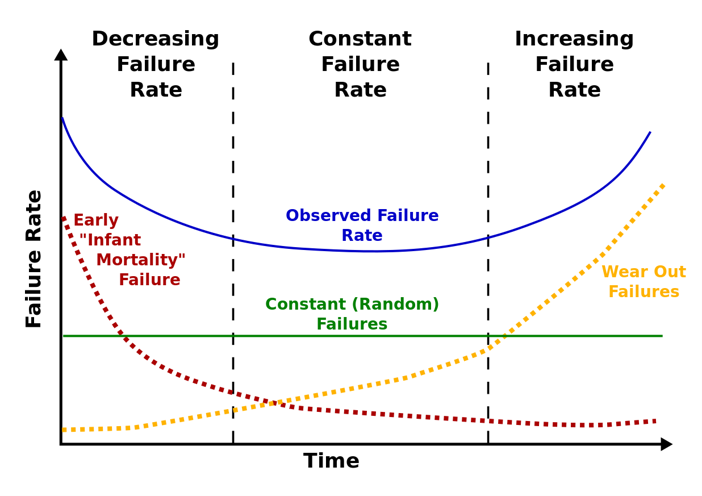

Complex Asset Failure Patterns

- P=Potential Failure

- Is an identifiable condition which indicates that a functional failure is either about to occur or in the process of occurring.

- F=Functional Failure

- The asset fails to fulfill the indented function.

Failure Effect Consequence:

The fracture of gear teeth has evident operational consequences. This failure mode results in extended downtime while the gear and pinion are replaced. If a spare is not available the downtime can be catastrophic.

What needs to be done to predict or prevent failure from tooth fracture:

On condition tasks need to be implemented to check for potential failures (crack formation, severe wear, and spalling), in order to avoid the consequences of a broken tooth.

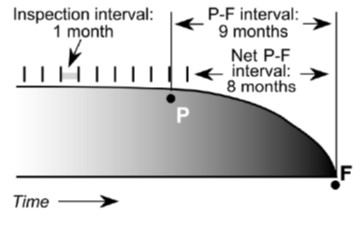

- Inspections of the gear teeth are necessary to detect crack formation, spalling, severe wear and other potential failures!

- These inspections must be done at intervals less than the P-F interval! Experience has shown that the time between crack formation and tooth fracture is often longer than 1 year.

- Regular visual/stroboscopic/photographic inspections, thermal imaging, vibration analysis, and lubrication analysis are also necessary.

Determine if one-time engineering or system changes are necessary:

- This will depend on the operating context of a particular gear.

Contingency Planning

Reports will clearly identify any cracks, fracture, severe spalling, severe wear, or tooth fracture that is present. These potential failures need to be addressed in order to mitigate the risk of functional failure and or reduce the consequences of a functional failure. Each gear set needs to addressed in its current operating context.

Key Questions:

- Is the gearing part of a single circuit where failure would bring the line or plant down resulting in lost production. Or is it part of a redundant circuit where failure would cause minimal lost production as material can be processed through the other circuit?

- What is the operating schedule of the gearing 24/7, 8 hours a day or once a week. This will help determine the impact of a functional failure.

- What is the age of the equipment in operating hours, gearing does demonstrate an increase in failure rate with age.

- What is the overall condition of the gearing, good, fair, serious, or critical?

What are the risks of tooth fracture?

- Broken segment wraps around and goes through mesh, the mill or kiln may jump the foundation. This can damage the footing, foundation, trunnion bearings or rollers, the cost of lost production and repairs can easily exceed $10M in mineral processing circuits.

- Load is now concentrated in a smaller area increasing stress resulting in complete tooth loss and loss of torque transmission.

- Load sharing with surrounding teeth decreases resulting in additional fractured teeth and loss of torque transmission.

- Vibrations increase causing damage to the bearing elements.

- Mill head bolts break distorting and damaging the mill shell

What is the plan if a crack, severe spalling, severe wear, or fracture is found on a ring gear?

Crack: A crack of any size is a critical potential failure that will eventually result in tooth fracture.

- Ensure a spare gear is available onsite, order one if one is not present.

- Have a gearing expert assess the crack size, orientation, and determine the risk of fracture in a given timeframe.

- If the risk of immediate fracture is high the site should plan to replace the gearing as soon as it is possible

- If the immediate risk of fracture is low repair actions such as relieving can be taken and planning for replacement can be scheduled at an opportune time

- Regular visual/stroboscopic/photographic inspections, vibration monitoring, and thermal imaging will enable the site to identify progressive macropitting and take action.

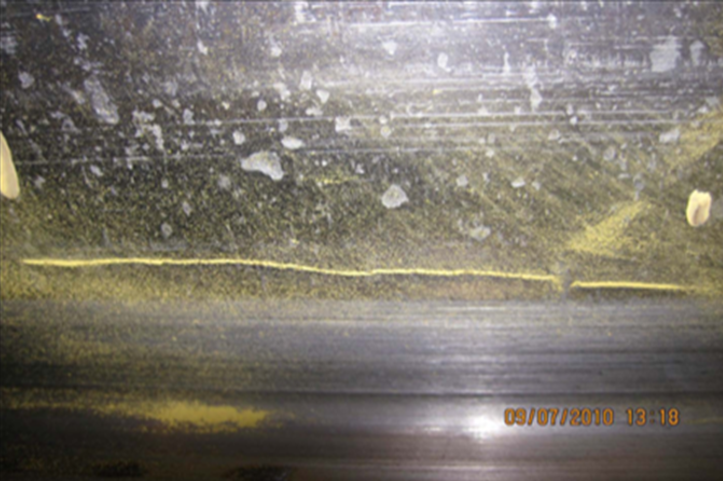

Severe Spalling: As macropits grow and coalesce they form large spalls which are highly prone to crack formation, and fracture.

- If the spalling is concentrated on one end of the face width, check the alignment with thermal imaging, and correct if misaligned.

- Review previous reports in order to determine the time of progression of the macropitting.

- If the gear has only run on one flank the gearing should be flipped before cracks form. If both flanks have operated ensure a spare gear is available onsite, order one if one is not present.

- Have a gearing expert assess the spall size, orientation, and determine the risk of fracture in a given timeframe.

- Regular visual/stroboscopic/photographic inspections, vibration monitoring, and thermal imaging will enable the site to identify progressive macropitting and take action.

Severe Wear: Contamination, poor lubrication, and gearing mismatch all lead to wear, when the teeth have become severely damaged from wear action must be taken.

- Determine the immediate cause of wear and correct, remove contamination, fix the lubrication system etc.

- Review previous reports in order to determine the time of progression of the wear.

- Have a gearing expert assess the wear, root cause, and determine the risk of crack or fracture in a given timeframe.

- If the gear has only run on one flank the gearing should be flipped before cracks form. If both flanks have operated ensure a spare gear is available onsite, order one if one is not present.

- Regular visual/stroboscopic/photographic inspections, vibration monitoring, and thermal imaging will enable the site to identify wear and take action before severe wear develops putting the gearing at risk for fracture.

Tooth Fracture: portions of a tooth or multiple teeth are missing, this is a critical potential failure, if not a functional failure.

- Ensure a spare gear is available onsite, order one if one is not present.

- Have a gearing expert assess the fracture, evaluate root cause, and determine the risk of additional fracture in a given timeframe. Recommendations for continued operation will depend on the location and severity.

- Review previous reports in order to determine the time of progression of the crack and fracture.

- The area around a minor fracture may be relieved to reduce contact stresses. This needs to be reviewed by a gearing expert.

- Regular visual/stroboscopic/photographic inspections, vibration monitoring, and thermal imaging will enable the site to monitor the area of concern prior to replacement.

Gear Flipping

- When the decision is made to flip a gear, a complete inspection per ASTM E2905 is needed to check for any cracks in the teeth or structure.

- If tooth or structure cracking is found flipping should be reconsidered and new gearing used.

- The split blocks need a thorough inspection.

- A new set of mounting and split hardware must be ordered

- Remove the old hardware without damaging the split blocks, avoid gas cutting.

- Once off the mill all components should undergo a thorough cleaning.

- Use a new pinion to mesh with the gear and set the pinion with root clearance NOT backlash.

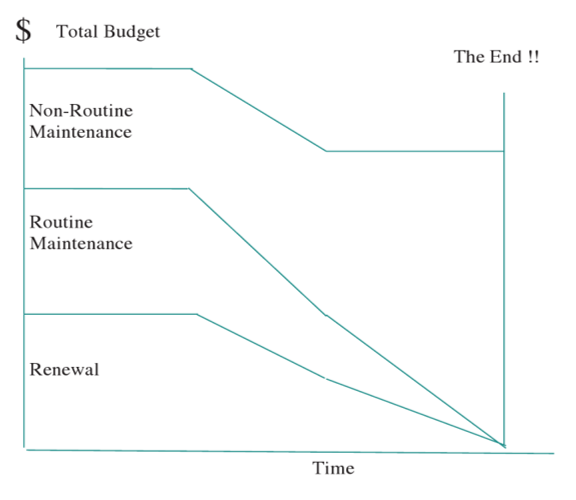

Market Conditions

- In our current market conditions particularly in hard rock mining, operators need to be aware of how budget cuts to routine maintenance will impact asset performance and failure rates.

- Sites need to make sure that they are doing the right tasks at the appropriate intervals to maintain the function of their assets. Evaluation of maintenance plans and strategies can eliminate wasteful or harmful tasks while implementing tasks designed to address specific failure modes reducing risk.

Avoiding the Asset Death Spiral

RCM Approach

Each girth gear system needs its functions and desired standard of performance clearly identified, in its present operating context.

- Determine how the gear system can fail to fulfill its functions

- Determine the causes of each functional failure (failure modes).

- Determine what happens when each failure occurs (failure effects).

- Classify the consequences of failure (failure consequences).

- Determine what should be performed to predict or prevent each failure (tasks and task intervals).

- Determine if other failure management strategies may be more effective (one-time changes).

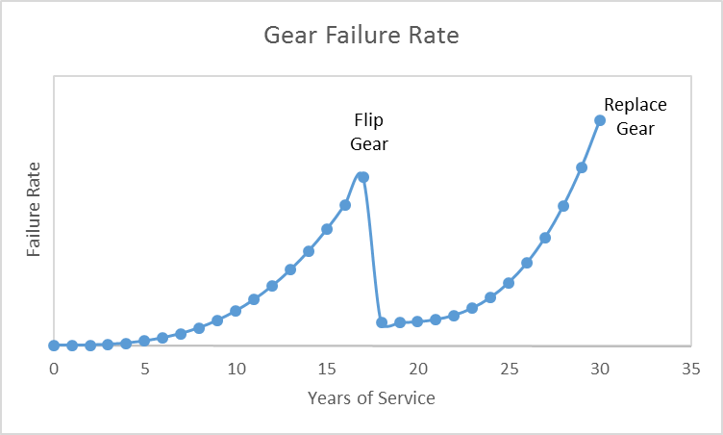

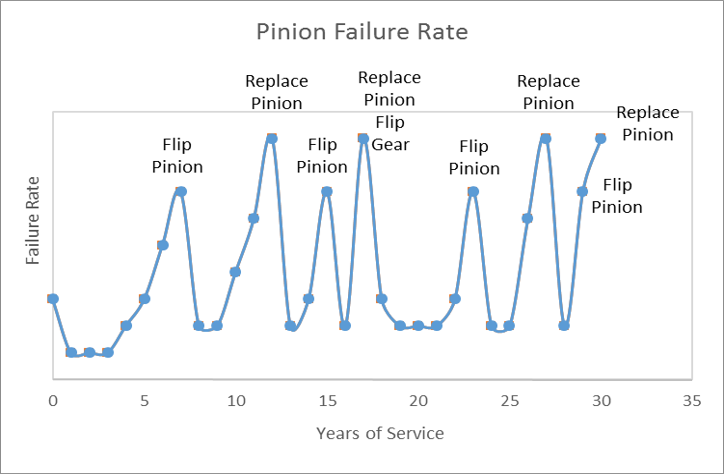

Classical View of Gear and Pinion Failure Rates

Cast vs Forged Girth Gear Designs

Steel is the preferred material for gear construction, ductile iron may be appropriate in certain situations

Cast Gearing

Advantages

- Cast gearing allows the manufacturer to optimize the gear structure to best support the rim.

- Can be manufactured in both the T and Y configurations.

- Provides a homogenous material from bore to rim.

- Previous manufacturers such as Falk had total process control.

- Alloys specifically engineered for girth gear service

- Decades of experience with mold design and solidification modeling

- Feedback between foundry and machine shop no third party vendors involved.

Disadvantages

- Inherently contains some porosity

- Inclusions may be present

- Material properties can vary based on section size, if not accounted for

- Inexperienced foundries may have problems with casting integrity, causing severe delays in production and high infant mortality rates.

Fabricated Gearing

Advantages

- Same rating as a cast gear of comparable rim material properties.

- Provides a more homogenous rim

- With proper reduction, inclusions and porosity are eliminated.

- Commercially available blanks with uniform material properties are used.

- Lead times are shorter than for cast gearing

- More options for supply

Disadvantages

- Proper welding techniques must be used under preheat in order to obtain a sound fabrication.

- Weld fillet radii need to be designed and specified to avoid stress concentrations.

- Fabrications may be prone to high cycle fatigue cracking in heavily welded areas.

- Can only be manufactured in T sections.

Ductile Iron, and new in AGMA 6014-B15 Austempered Ductile Iron, Self Aligning Drives.

Ductile Iron

Ductile Iron can provide a cost effective gear design under certain design criteria. However this material will rate less than a steel gear of similar dimensions and hardness levels.

Austempered Ductile Iron (ADI)

Can provide rating increases over ductile Iron and steel gearing, however large scale austempering is not available. These gears are manufactured in many segments, increasing the number of joints and potential failure modes associated with these joints.

Self Aligning Drives

Self aligning drives are designed to allow the pinion to float to maintain alignment with the ring gear. These drive systems can offer rating increases over non self aligning systems and typically use case hardened pinion gearing.

The self aligning apparatus and drive system is complex and integrated, any failure of this system can cause extended downtime before a specialist from the manufacturer can address the issue.

Often use recirculated oil systems, which are filtered but often use lubricants with to low a viscosity for the gearing in order to lubricate the bearings.

Conclusion

- Steel is the preferred material for gear construction, ductile iron may be appropriate in certain situations.

- The rating standards do not differentiate between fabricated or cast steel construction.

- There are pros and cons to each design type.

- Be cautious of cast gears from manufacturers that purchases cast blanks from low cost countries.

- Be cautious of fabricators which do not regularly produce ring gear blanks. Ask the manufacturer if they do their own fabrication or if it is outsourced.