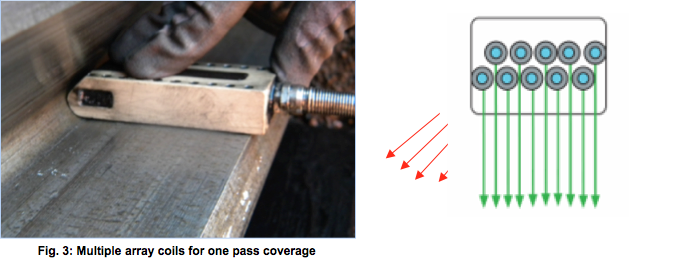

The advantage of inspecting mill gear drives utilizing ASTM E2905 over Eddy Current, or for that matter, all other methods of NDT for gearing applications, is recorded data is utilized. ASTM E2905 is cleaner, faster, documentable, and covers a larger area in less examination time better than any other traditional Non-Destructive Testing methods today for gearing applications. Drastically reduces inspection time. Covers a large area in one single pass. Provides real-time mapping of the inspected region, facilitating data interpretation. Improves reliability and Probability of Detection (POD). Unlike some other inspection methods, this will size cracks accurately, and all of the data is electronically archived for future reference in C- Scan imagery.

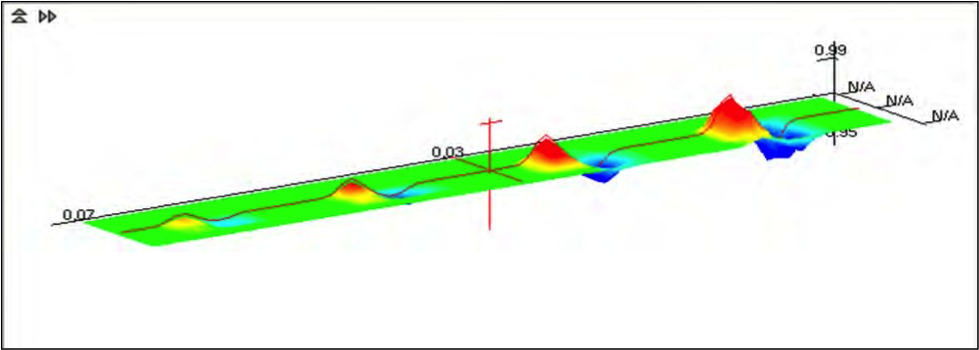

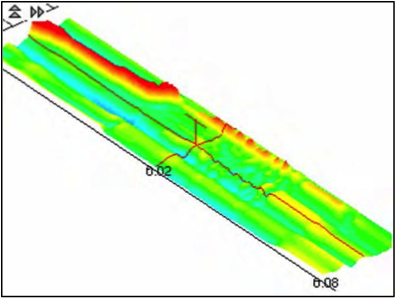

The main advantage of E2905 are the 2 and 3D displays that are produced. With these types of displays, it is possible to characterize the defect.

Eddy Current (Disadvantages)

For example, Eddy-Current gives us only a phase angle and amplitude signal that we must interpret and thus make a judgment call on the type of defect. This judgment call relies solely on the inspector. See Figure 1.

- Single Eddy Current Coil Must Be Moved across the addendum, dedendum and root.

- Difficult to achieve full coverage of gear flank and root. Discontinuities can be missed. Figure 2

- 15 to 20 Hour Time Frame.

- Non-compliance with ASTM E2905.

- Hand Written Reports

ASTM E2905 (Advantages):

- With 2 and 3D Dimensional Isometric Displays, we can see the defects as it is in the material.

- Knowledge of the defect type helps in determining the root causes and eliminates the potential for errors.

- The system will display the actual characteristics of the defects, (see Figure 3), this is a Pit.

Figure 3: E2905 illustrating a Pit on a gear flanks

- Using E2905, it is very easy to see a crack or a pit on a gear tooth compared to interpreting the Eddy Current signal in Figure 5.

- In other words a pit looks like a pit (see Figure 3) and a crack looks like a crack (see Figure 4).

- E2905 is used in this configuration and has consistently shown the ability to discriminate between dents, pits and cracks.

Figure 4: E2905 illustrating a crack on a gear flank