Over the years, girth gear cleaning, that use high viscosity, asphaltic based lubricants or synthetic lubricants has become something to be avoided at all costs. Global’s girth gear cleaning procedure, not only simplifies the cleaning process, but reduces the numerous hours of labor. The actual time of cleaning a 36′ girth gear is under an hour. This is excellent for Pinion change-outs.

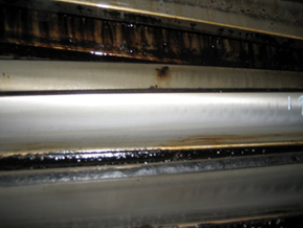

The ability to fully visualize gear teeth is critical for a true gear inspection or audit.

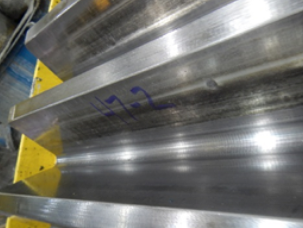

Utilizing the E2905 method of gear inspection, there is no need to wipe the gear teeth down after by hand or to pressure wash the gear teeth to remove residue as in the preparation of Magnetic Particle or Dye Penetrant inspections. Use this cleaning procedure with ASTM E2905 Standard Practice for girth gear inspections for excellent results.

Gear Engineers utilize visual interpretation to analyze the gear teeth condition, such as contact patterns and wear patterns; hence, a clean gear set is a must. Clear or translucent lubricants still require cleaning to conduct a thorough visual inspection, as the lubricant can obstruct critical details on the tooth surface.

Global uses CLEANSOLV High Flash EP Low VOC for all their cleaning requirements.

CLEANSOLV High Flash EP Low VOC formulation contains high levels of EP additives to protect the gearing during the cleaning process and is designed to clean mill and kiln girth gears prior to inspection while minimizing downtime. This is accomplished by cleaning the girth gear while in production.

Procedures that used to take days can now be completed in less than an hour. Using this procedure, gears are safe from damage due to the specifically formulated CLEANSOLV High Flash EP Low VOC. As a result, gears are fully cleaned and ready for inspection or pinion change-outs faster than before.