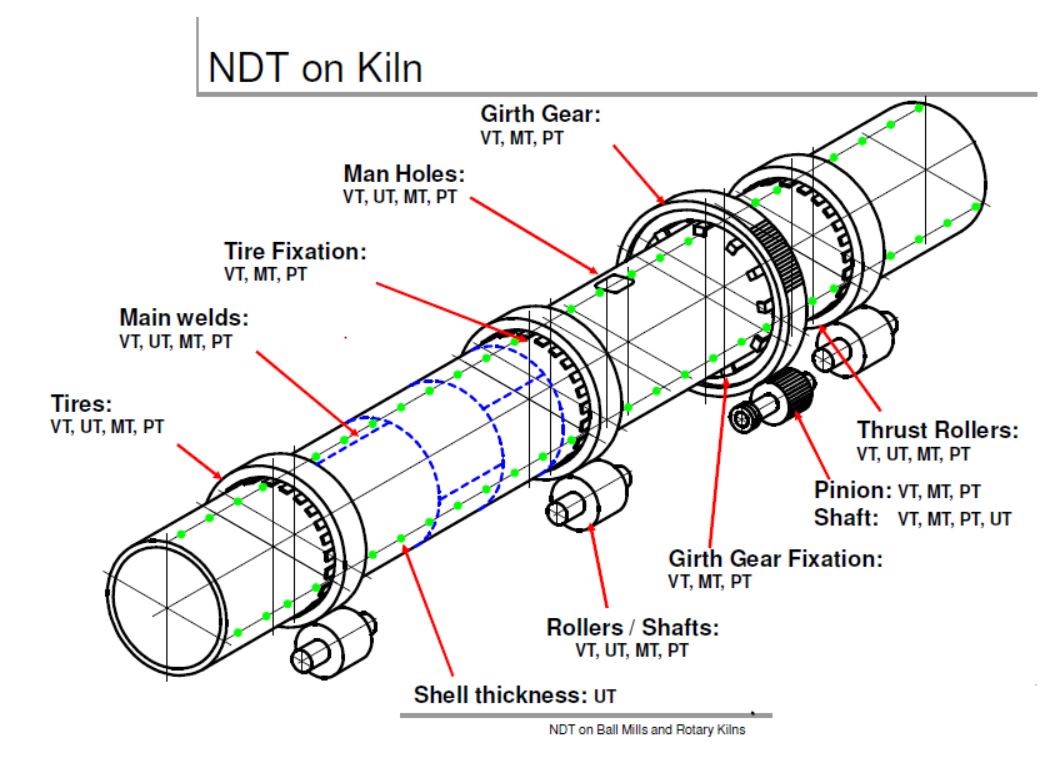

A Kiln can be immobilized by the failure of a high cost component such as a tire, roller, or shell. At a minimum, annual kiln inspections for these components should be part of an overall preventative maintenance program to minimize downtime and maximize the life cycle of these components.

Our technicians and engineers are experts in the design, procurement, and operation of mill and kiln gear drive trains, shells, heads, trunnions, riding rings, and rollers. This approach enables us to offer complete solutions to our customers asset management needs.